Epoxy flooring in Houston needs to be durable enough to withstand the city’s intense heat and humidity. To help you navigate the industry, here’s a breakdown of important concrete coating industry terms, categorized for easy understanding.

Concrete Coating Components

Understanding what goes into your epoxy floor can help you see why it’s such a durable and versatile choice for your Houston space.

- Resin: One component of the 2-component coating mixture. Resin is the Part A base component. When mixed with its Part B activator, the mixture begins to cure.

- Hardener/Activator: The second component of the 2-component mixture. The activator causes the resin to solidify, creating a mixture, that once cured, provides a strong bond with the substrate below.

- Mica Flakes: Natural mineral flake that can be added to a flake blend to create a more reflective flake finish. Vintage Mica is an example of a mica-infused flake blend, popular in Houston homes and businesses that want a unique look.

Concrete Coating Types: Coating System Building Blocks

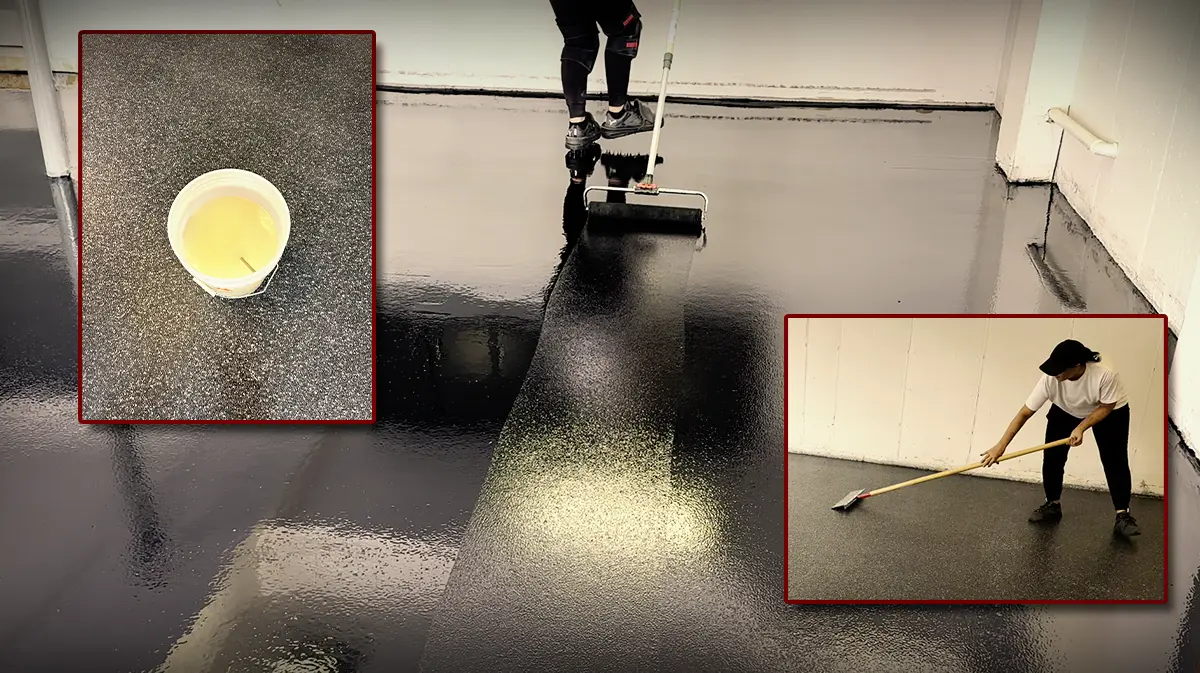

The various coating types – epoxies, polyurea-polyaspartics, and polyurethanes – are layered to create a “coating system”. Coating systems use multiple layers of one or more coating types. The coating types used depend upon the type of protection required for your unique space.

- Epoxy Coating: A slow-cure coating that goes down thickly (epoxies are “high-build” coatings). Because they cure slowly, they have time to deeply penetrate and strongly bond with the concrete substrate. Hence, epoxies are excellent primer coats. They can also be used as color coats or top coats, creating a tough, chemical-resistant surface. Albeit, epoxies are sensitive to UV light (they fade) and so use is restricted to interior spaces if used as top coats.

- Polyaspartic Coating: A fast-curing, UV and chemical-resistant coating; perfect for the Houston sun. They’re superb top coats and cure quickly, so they provide a fast “return-to-service”. However, polyaspartics can only be applied thinly and cure so quickly that they fail to penetrate and strongly bond with concrete. Hence, while excellent top coats, they’re poor direct-to-concrete primer coats, especially in the presence of concrete moisture.

- Polyurethane: A flexible, protective topcoat that resists wear, UV damage, and chemicals. Excellent for outdoor patios and walkways. However, due to their poor resistance to “hot-tire transfer”, polyurethanes should not be used in garages.

Everyday Terms

These terms are often used by homeowners and business owners when referring to epoxy flooring, helping to demystify industry jargon.

- Garage Floor Coating: A layman’s term often used to describe layered epoxy or polyaspartic coatings applied to protect garage floors. In Houston, garage floor coatings guard against heat, moisture, and chemical spills.

- Concrete Paint: Another casual term sometimes used to refer to epoxy coatings. Unlike actual paint, epoxy bonds to the concrete and provides far more protection, making it a better option for long-lasting durability. Paint is a DIY solution that may last a year.

- Flake Epoxy Floor System: In these coating systems, decorative flakes are broadcast into the epoxy primer coat. They create a textured, more slip-resistant surface. In Houston, these flakes not only improve safety but provide added durability and help disguise imperfections.

Conclusion

In Houston’s hot, humid climate, having a durable floor coating is key. Whether you’re looking for protection against moisture, heavy traffic, UV rays, or chemical spills, understanding these terms will help you choose the best epoxy flooring option for your home or business.