Houston homeowners know that between high humidity, sudden rainstorms, and scorching heat, your garage floor sees a lot of stress. That’s why the base coat of your garage flooring system matters more than you might think. At Garage Floor Coatings of Houston, we use garage floor epoxy as the foundation of every system—for one key reason: it prevents the problems we see far too often when a quick-cure polyurea or polyaspartic coating is used as the base coat.

Problem #1: Peeling and Lifting

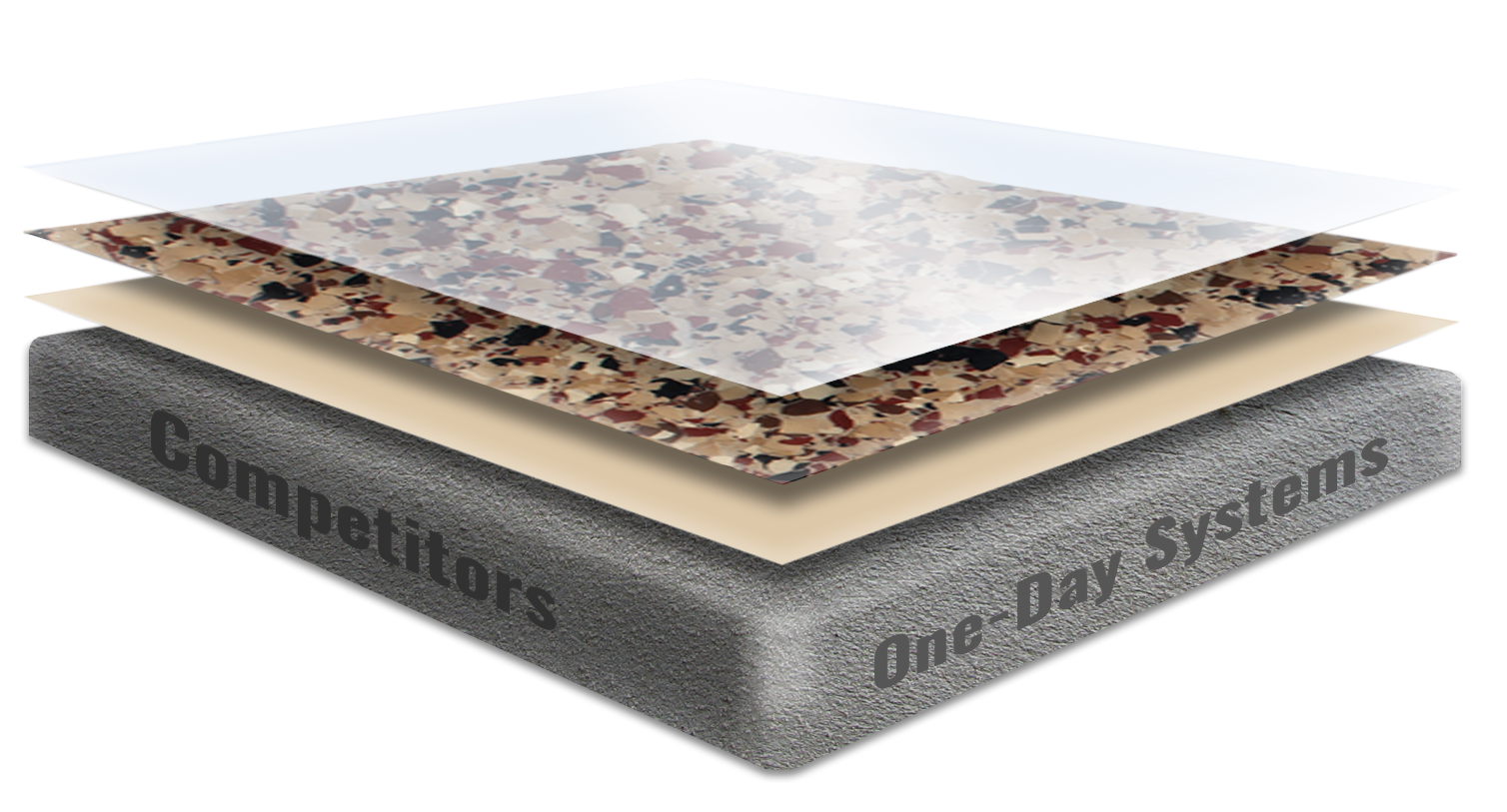

Some companies offer “1-day” installations using a polyurea or polyaspartic as both the base coat and single clear topcoat. (They have to use them to get the installation completed in the promised one day). The speedy install sounds convenient, but when a polyurea or polyaspartic is used as a base coat, fast-curing often means poor adhesion, especially in the presence of moisture.

- What can go wrong?

Polyurea-polyaspartic coatings cure very quickly (in under 1 hour). They cure even quicker in the presence of humidity in the air and/or medium to high levels of moisture in the concrete. So quickly, in fact, that the applied polyurea-polyaspartic base coat doesn’t have time to deeply penetrate the concrete. The result? A thin, weakly-bonded base coat that’s susceptible to peeling as moisture vapor transmission creates upward pressure on the coating system. This is especially true in hot and humid Houston.

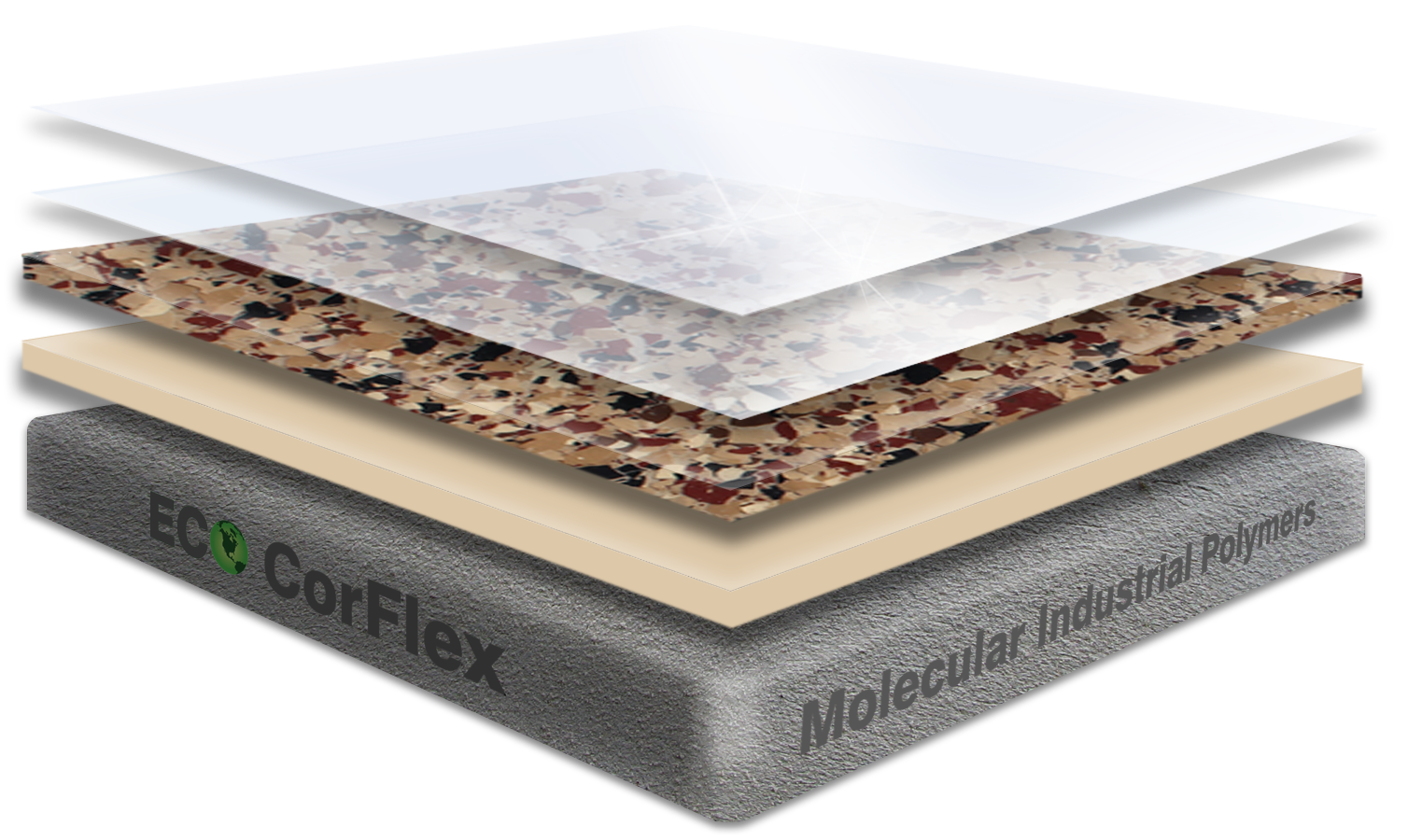

Conversely, garage floor epoxy, specifically moisture-mitigating, 100%-solids epoxy, are high-build coatings that cure slowly and deeply penetrate the concrete slab. When used as base coats, the thick epoxy layer acts as a moisture vapor barrier—so your floor stays put.

Problem #2: Trapped Moisture

Houston’s high humidity isn’t just uncomfortable—it’s a threat to garage flooring. Moisture vapor rises up through the porous concrete slab, especially after storms or during seasonal transitions.

- What can go wrong?

If the base coat isn’t built to handle it, moisture vapor transmission (MVT) can create a hydrostatic pressure over time that causes the coating to bubble, blister, and eventually separate from the slab.

However, a slow-curing, 100%-solids epoxy is a high-build coating. It forms a strong moisture mitigating layer that a polyurea or polyaspartic base coat just can’t match. Acting as a moisture vapor barrier, it mitigates against moisture-related issues. And that’s critical in the Gulf Coast climate.

Problem #3: A Thin Base Means a Fragile Floor

In addition, due to the chemistry of polyurea-polyaspartics, they simply can’t be applied thickly (only thin layers cure properly). That leaves the floor more vulnerable to hydrostatic pressure from below. Conversely, the thick, highly penetrating epoxy layer, creates a durable base.

Why GFC Houston Chooses Epoxy First

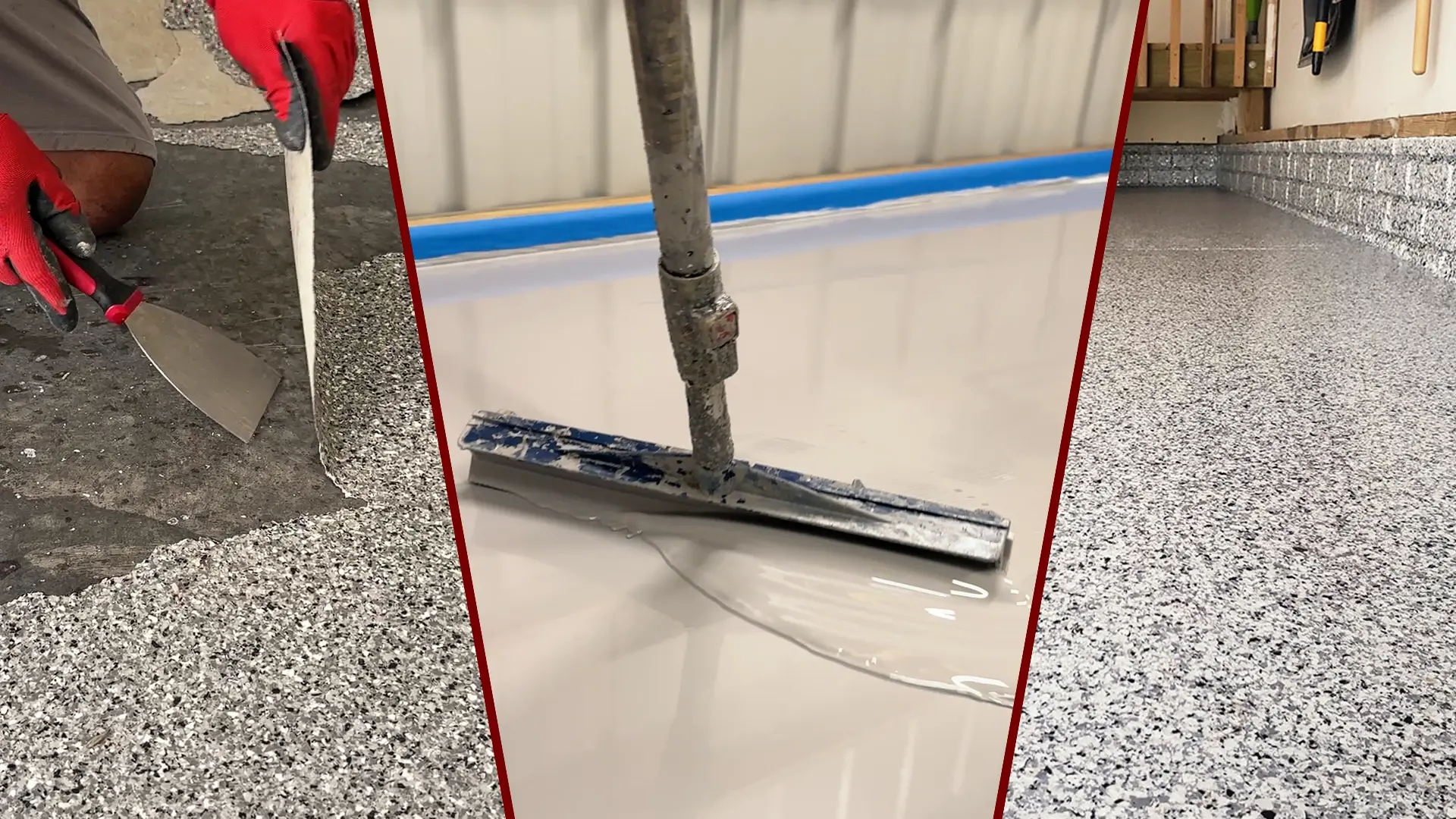

Our 2-day system includes:

- A deeply-penetrating, moisture-mitigating garage floor epoxy base coat

- Two (not only one) 100%-solids polyaspartic topcoats for long-term protection and UV stability

Want a garage floor that won’t quit in Houston’s extreme weather? Contact Garage Floor Coatings of Houston and get the strength that starts at the base.