Houston’s climate is notoriously tough on garage floors. Between high humidity, torrential downpours, and sweltering heat, your concrete surfaces endure constant environmental stressors. When it comes to installing epoxy flooring in your garage floor as a means of protection, there’s a choice. 1-day polyurea-polyaspartic systems versus 2-day epoxy-polyaspartic systems.

Your choice can have lasting consequences. While the 1-day system might seem like a convenient option, it’s speed over quality. The reality is that the 2-day system is far more effective in terms of durability and moisture protection.

What Exactly is a 1-Day System?

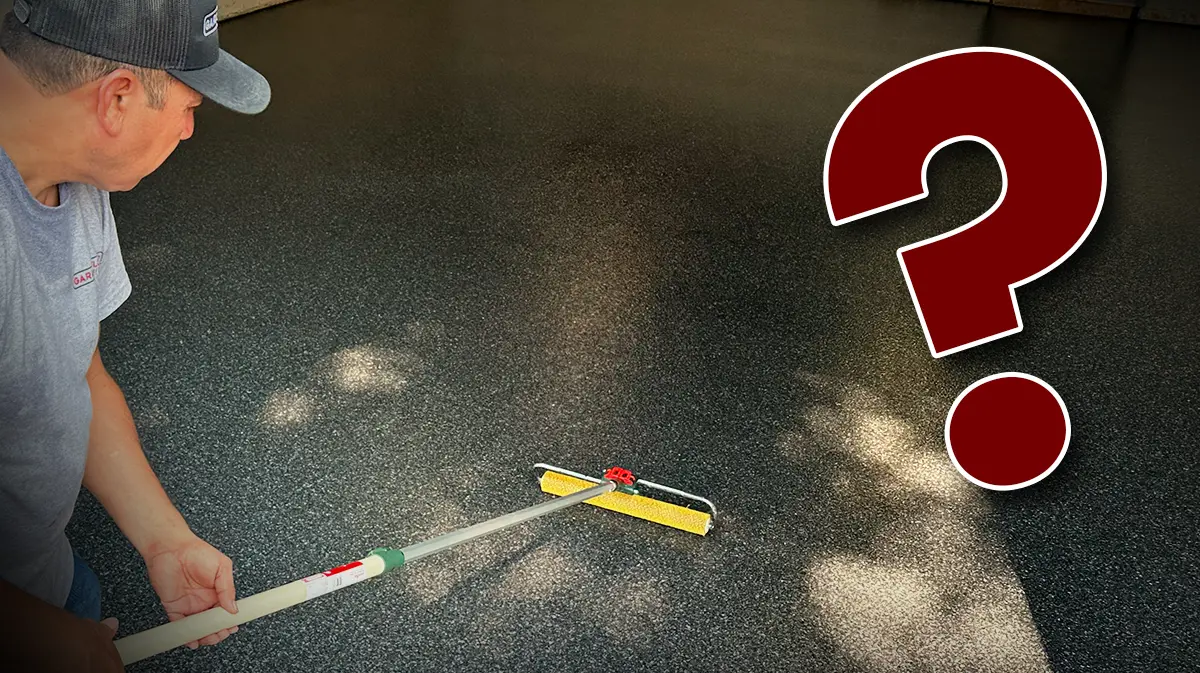

The 1-day system has gained popularity primarily because of its fast application. A contractor can apply a polyurea-polyaspartic coating in a single day, allowing you to use your garage again within 24 hours. The process involves applying a thin polyurea primer coat, broadcasting the chosen flake blend, and topping it all with a single polyaspartic topcoat. Both the polyurea and polyaspartic are quick-curing coatings which allows for the 1-day application.

Although this may sound ideal, the speed of the installation can result in several issues. Polyurea-polyaspartic coatings are designed to cure rapidly, and they cure even faster in the presence of medium to high concrete moisture (< 1 hour). However, this rapid curing leaves little room for thorough penetration and bonding with the concrete substrate. As moisture wicks up through the concrete, it creates a pressure beneath the primer coat. Enough pressure to delaminate a weakly applied coating system.

Installing Epoxy Flooring: How Does a 2-Day System Work?

In contrast, a 2-day system allows for a more methodical approach to coating your garage floor. On the first day, a slower-curing, moisture-mitigating 100%-solids epoxy primer is applied to the concrete. The epoxy is a high-build coating that deeply penetrates the concrete (it has the time to) and thus acts as a moisture vapor barrier. It prevents moisture and the resulting hydrostatic pressure from lifting the primer coat (as it can with a wafer-thin, poorly penetrating polyurea primer). Since Houston often deals with high humidity, this moisture barrier is critical to preventing future peeling, bubbling, or delamination of the coating.

On the second day, two layers of 100%-solids polyaspartic topcoats are applied. (1-day systems use less than 100%-solids polyaspartics and only apply a single coat!). These topcoats offer high levels of UV protection, chemical resistance, and protection from the harsh elements Houston can throw at your garage. The result is a thicker, more durable coating that can handle heavy traffic, fluctuating temperatures, moisture infiltration, and even the infamous hot-tire transfer that can ruin less durable coatings.

Installing Epoxy Flooring: Why a 2-Day System is the Best Choice for Houston

Houston’s year-round humidity makes concrete moisture control an essential factor when selecting a garage floor coating. Without a moisture-mitigating primer, the coating may fail prematurely due to moisture vapor transmission—a common problem in Houston where the concrete absorbs ground moisture.

A 2-day system offers superior protection because the 100%-solids epoxy primer creates a solid bond with the concrete, sealing it against moisture. The epoxy penetrates the surface, filling in pores and creating a protective barrier. On day two, the dual polyaspartic topcoats are applied, providing UV resistance and protection from hot tires, chemicals, and daily wear.

This layered approach ensures the longevity and durability of your garage floor, making it a perfect fit for Houston’s challenging weather conditions.

How Houston’s Heat Impacts Garage Floors

In addition to moisture, Houston’s sweltering heat can wreak havoc on garage floor coatings. The polyaspartic topcoats in the 2-day system are specifically designed to handle extreme UV exposure. Without UV protection, your garage floor could fade, discolor, or lose its finish over time. 1-day polyurea-polyaspartic coatings do provide the UV stability, but fail to mitigate for moisture under medium to high concrete moisture conditions. A little hydrostatic pressure, and “pop” goes the 1-day coating.

Why Settle for a Short-Term Fix?

While the 1-day system might be tempting for its quick turnaround, it’s not built to last in a demanding climate like Houston’s. The lack of a moisture barrier and the thinly layered coating can lead to premature failures, forcing you to spend more on repairs or re-coatings. The 2-day system, however, offers a lasting solution that handles high moisture, UV, impacts, and staining…including hot-tire staining. Ensure your garage epoxy floor stays in top shape for years to come with our 2-day epoxy and polyaspartic full flake coatings.

Call GarageFloorCoating Houston for a Free Quote

If you’re in Houston and want a garage floor that’s built to withstand the elements, it’s clear that the 2-day system is the best choice. Contact Garage Floor Coatings of Houston today for a free consultation, and let us help you choose the right system for your home.